Series Two Chair

A Step-by-Step Project Journal of Joe's Design, Fabrication and InstallationSeries Two Chair: Start of Fabrication

The chair starts fabrication with cutting aluminum tubing to match a side profile template.

Series Two Chair: Welding Parts Into Frame

Once the parts are cut they are welded into a frame and subsequent frames are matched to the first one.

Series Two Chair: Specially Designed Framing

The frame was specially designed so that the welds did not interfere with the formed panels that would later be bonded to this structure.

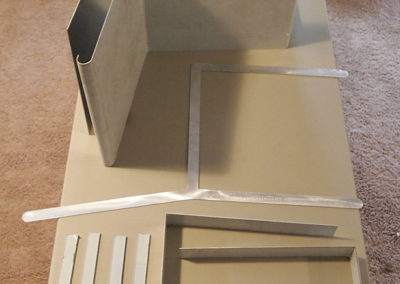

Series Two Chair: Water Jet Cut Parts

Here is the battery of formed and water jet cut parts from my supplier that will be the skins for the chairs.

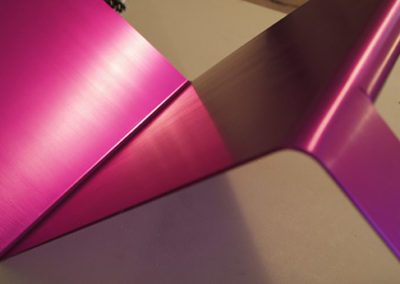

Series Two Chair: Hand Brushed Panels

Once the panels are fit they are sent to the anodizer or painter for final finish. We hand brushed this panel and it has a magenta color anodize.

Series Two Chair: Hand Craftsmanship

A lot of hand work goes into fitting and bonding the panels to the frames. That is Craig an architect friend of mine helping get ready for a show.

Series Two Chair: Rearview

The back view. The circle at the base of the seat is where my machined logo emblems go.