Private Ferrari Museum: Radiused Display Casework with Hidden Door

A Step-by-Step Project Journal of Joe's Design, Fabrication and InstallationPrivate Ferrari Museum: Before we got started

Here is the corner of the museum space before we installed the display case. Notice the HVAC unit that we could not move. The corner had weird energy.

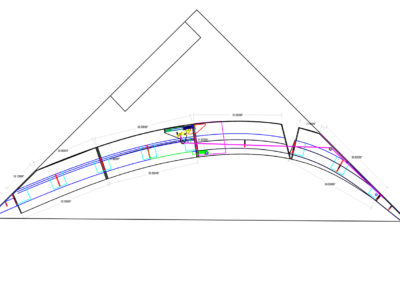

Private Ferrari Museum: Final design

The final design for the showcase was an irregular curve in plan. The entire piece was to be fabricated by welding nearly 1,000 ¼” water jet cut aluminum pieces together. You can see the cabinet that becomes the door and the trick mechanism that releases it.

Private Ferrari Museum: Fabrication begins

Our fabrication process began with sanding the edges of many hundreds of parts in a 6 step sanding process. Final polishing was reserved for the very end before the unit left the shop. We used an assortment of Dynabrade air sanders and a new high tech 3M sander that quickly acquired the name “the hot rod” because of its power and overall insane performance.

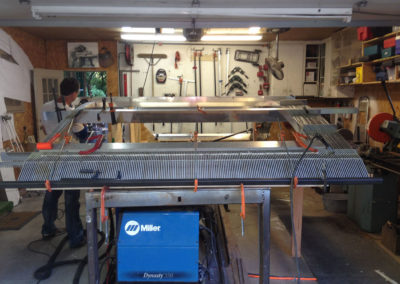

Private Ferrari Museum: Meeting design challenges

Here is the right side of the grille jigged up prior to welding. Keeping every part evenly spaced and square was certainly the challenge here. Ultimately the hardest thing though was the welding because of the limited surface area to apply concealed welds and also I had a broken foot so I was in a cast. I use a foot pedal to weld. But what was in our favor was that when welded along the back of the parts the welds were imperceptible when the grille was viewed from the front.

Private Ferrari Museum: Hidden release lever design

The hidden release lever was really a trick combination of parts that looked identical to the other ones near it. In reality they were quite different and were part of a removable module that incorporates a pivot hinge, rubber bumpers, brackets, and a control horn for the release cable. Getting this module to align with the other 200 or so grille parts in that column was difficult.

Private Ferrari Museum: Building the unit square and true

I think at one point we had what seamed like every clamp we had on this piece. We spent great care to build the unit square and true. This would later prove invaluable. The assembly was one of those things that seemed fairly easy when I designed it, but it proved anything but. We fought this thing all the way to the end. Again I had to weld it standing up and my broken foot was a major drag. But I did get comfortable with it by the end and a week of solid welding in really odd positions. Mostly fillet welds traveling upward. Thank goodness for the Dynasty Tig. It never failed me.

Private Ferrari Museum: Large project bracing

Here you can see the overall size of this piece. We built special jigs at either end that worked well to provide basic stability and then added additional braces as needed. The amount of braces would be many by the end. The vertical columns of the grille were essentially very fragile and had to be supported at all times to prevent damage.

Private Ferrari Museum: Burning the midnight oil

We burned plenty of midnight oil getting this project out on time. I think we worked on it for two weeks straight before it was finished. Meanwhile other work spilled out into outside parts of the shop.

Private Ferrari Museum: Ready for final polishing

Here is the finished grille unit ready for final polishing. Getting the piece into this position from just ten feet away took ten men, four engine hoists and about four hours. This was a very awkward structure to say the least. Fortunately there were many upsides to this configuration. We added the plywood the next day and this was extremely helpful in keeping the work stable and square when it was moved.

Private Ferrari Museum: Moving day, fragile cargo

Moving day! This was extremely nerve racking and often I had to look away. Luckily I had Frank to keep things calm and smooth. Every one becomes a bit of a know it all in these kinds of situations. But Frank stepped up and nothing was damaged. Also he drove to the site with the ultra fragile cargo. We had cones mounted on the outer corners and used a leading and trailing car to create a sort of safety zone on the road.

Private Ferrari Museum: Careful transport

The driveway that leads to this private museum space is super narrow, sloped, and curved. We at one point had to jack the trailer up and literally move it sideways several feet to clear a retaining wall that was in our way. The maid came through with a cooler full of Tamales that her husband makes and sells. They lifted spirits once we were finished.

Private Ferrari Museum: Final resting spot

This is the only shot I have of the grille after it had been set in its final resting spot. No one but me believed it would have enough ceiling to rotate up on its feet but it ended up clearing by 1/8”. Some times you just get lucky because I did not really plan it that way. Anyway the project was past a major hurdle but we were far from done. Actually fitting it in perfectly and anchoring it down was extremely tedious and time consuming. We used lots of tricks to actually get the unit where we wanted it. You can see in later images that the right side grille needed too match up perfectly with the adjacent sheet rock. And the left side matched up with a corner line in the sheet rock.

Private Ferrari Museum: Anchoring the unit

Before we actually anchored the unit for good we had to get the outer cabinets finished and installed because once the grille was pushed against the wall in its final location these cabinets would be impossible to install because they had to slip in from the back. You can see here how the grill fits perfectly on the right side just above the floor and just below the ceiling. And then the floor slopes down over two inches and the ceiling slopes almost two inches.

Private Ferrari Museum: Spring loaded release mechanism

A shot of the spring loaded release mechanism that looks sort of lethal. Also you can see the fancy holes we milled for the led’s and cover plates along with the wire channel. A tiny brass channel was painted to match and slipped in this slot.

Private Ferrari Museum: Locked into place

Finally the grille is locked in to its home. I could not of been happier with the fit. It was dead on as we would say. Frank is testing the swing of the door. You can see us fabricating and installing this door in our “JMS bookcase door fabrication” video.

Private Ferrari Museum: Perfect fabrication and fit

Here is a good shot of the right side grille pieces where they meet the sheetrock.